Explore the use of cotton inspection equipment at room temperature

1. To use some cotton inspection instruments at room temperature, you must

use standard cotton samples (hereinafter referred to as standard cotton

samples)

(If you buy our company's KX175-1, KX730, the company will provide a set of

standard cotton samples)

Because at room temperature, the physical properties of cotton will change

with environmental conditions (temperature and humidity). If you test the

micronaire value, when you weigh the cotton, you will find that the weight

changes with the temperature and humidity. On a dry day, the weighing of cotton

is lighter than 8 grams, and the weight is heavy, and 8 grams of cotton is less.

This is the same as the micronaire value measured on 8 grams of cotton on rainy

and dry days. Not the same, the difference is huge. The same length will also

have different measured data under different environmental conditions.

How can the correct data be measured under different environmental

conditions? It is necessary to balance the standard cotton sample and the tested

sample in the same environment. First check with a balanced standard cotton

sample (close to the selected sample data), if it is within the tolerance (for

example, the index of KX175-1 is 0.05 micronaire, and the length of KX730 is

within 0.5mm), and then Test the tested sample, so as to ensure the correctness

of the tested sample data.

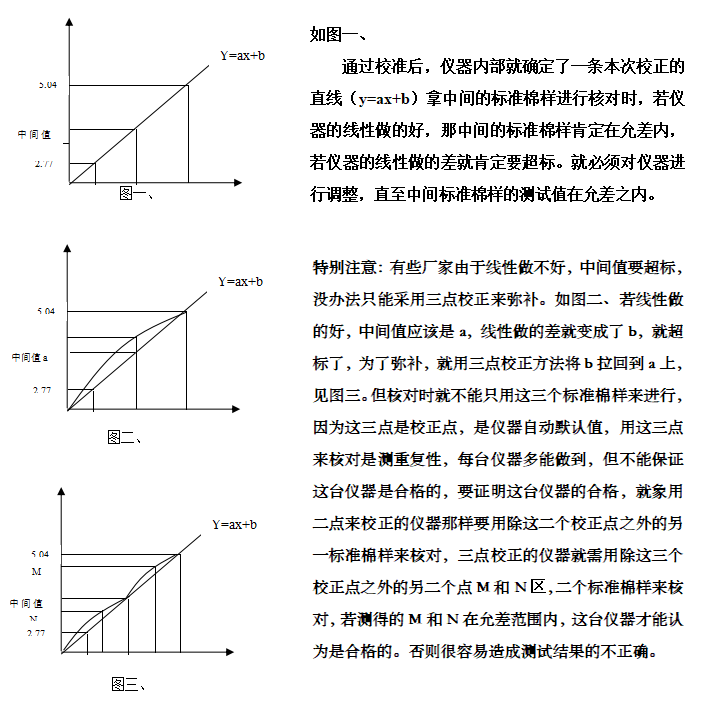

If the tolerance is exceeded, the lower and higher standard cotton samples

must be used for calibration. After the calibration is completed, the standard

cotton samples of the intermediate value must be used for verification. The

tested samples must be tested within the tolerance range. Ensure the correctness

of the tested sample.

2. When calibrating, use the lower and higher two standard cotton samples

for calibration. The value of the test sample should be between the two

calibration cotton samples. If you use 2.86 and 5.04 standard cotton samples to

calibrate, the value of the tested cotton sample should be greater than 2.86 and

less than 5.04, otherwise the measured results may be out of tolerance. (I will

introduce it to you if I have time.)

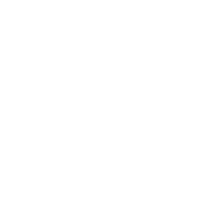

3. The judgment of instrument linearity is also very important

(Generally good instruments are two-point calibration)

We have the opportunity to discuss together again, such as how to eliminate the return error of the pointer instrument, etc., hoping to allow users to buy a good instrument and use the instrument well to ensure that the measured data is correct.

The browser own share function is also very useful~

The browser own share function is also very useful~